Team Lights Promising Way to Future of Solar Panel Production

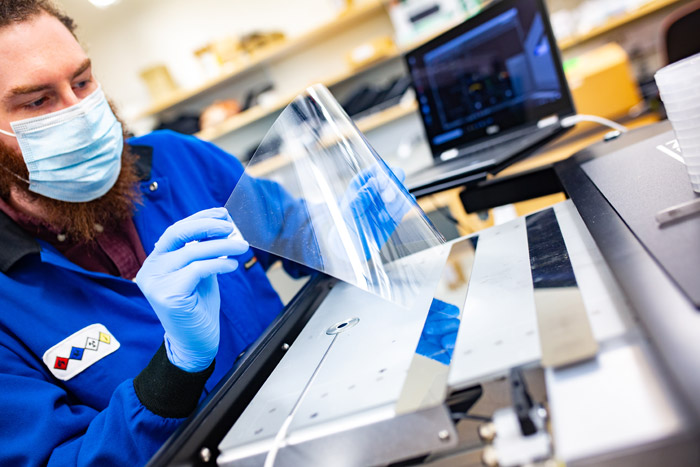

The University of Texas at Dallas researchers have demonstrated that a technique called photonic curing can be used to manufacture thin films used in flexible electronics one million times faster than traditional methods. The experiments could help pave the way for the large-scale production of devices ranging from wearable sensors to solar panels.

Researchers led by Dr. Julia Hsu, professor of materials science and engineering and the Texas Instruments Distinguished Chair in Nanoelectronics in the Erik Jonsson School of Engineering and Computer Science, published a series of studies about the method. One study, which details fabricating flexible perovskite solar cells using this process, was published early this past year in Frontiers in Energy Research.

Hsu’s research aims to solve a problem that has prevented large-scale manufacturing of flexible electronics and solar panels: the need to reduce the amount of time for the slowest part of production, which is called annealing. In this stage, the thin film must be heated to high temperatures, a step that can sometimes take hours and make production costly.

Hsu likened the traditional annealing process to cooking a long pizza that moves on a conveyer slowly through an oven. To make pizza faster, the time in the oven must be reduced. Also, heating the pizza to too high of a temperature would damage the crust.

“If you need to anneal the material for minutes, sometimes hours, that’s going to slow down how fast you can make flexible film. We want to make films fast so that we can take advantage of the economy of scale,” Hsu said. “My group is looking at using millisecond light pulses to convert materials instead of using conventional heating processes to do the annealing.”

“To meet the energy in this country or in the world, we need a lot more renewable energy. And to combat climate change, we need a lot more rewable energy of all sorts”

Dr. Julia Hsu

Professor of Materials Science and Engineering and the Texas Instruments Distinguished Chair in Nanoelectronics in the Erik Jonsson School of Engineering and Computer Science

The research was conducted in collaboration with NovaCentrix, an Austin, Texas-based company that makes photonic curing equipment. Photonic curing is a novel technology that is currently used to sinter, or coalesce, printed metal nanoparticles.

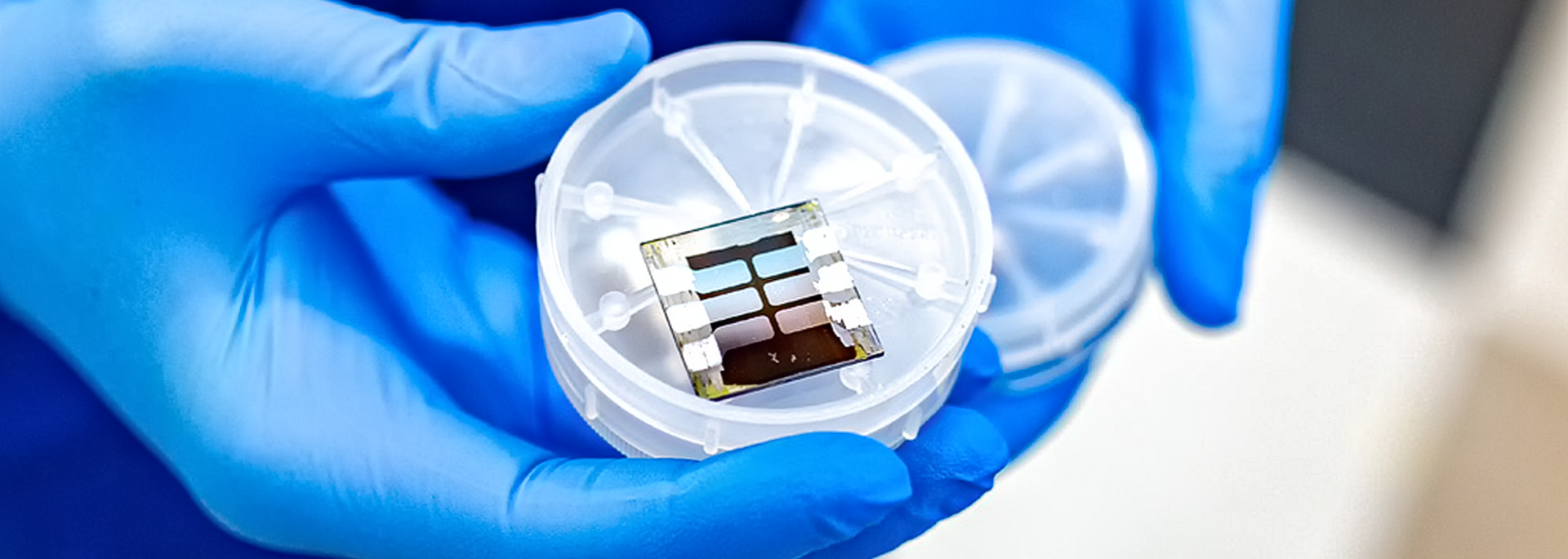

Flexible electronic devices are made of different thin films. In the case of the solar cells with which Hsu is working, one layer is halide perovskite, a family of materials that can be used to create solar cells that have shown potential for high performance and low production costs; the other is an oxide layer that transports the electric charge generated from sunlight.

Hsu was awarded a $800,000 grant (DE-EE0009518) from the agency in 2021 to apply photonic curing to fabricating flexible, transparent electrodes that will enhance the commercial viability of perovskite solar panels. The DOE’s goal is to increase the use of solar energy and cut the cost of its generation in half by 2030.

Hsu’s project is in collaboration with NovaCentrix and Energy Materials Corp., a Rochester, New York-based company that specializes in roll-to-roll manufacturing of perovskite solar panels.

Hsu, who joined UT Dallas in 2010, began her research on solar cells as a scientist in the Center for Integrated Nanotechnologies at Sandia National Laboratories. She said making solar cells less costly to produce is critical to increasing their use.

“To meet the energy demands in this country or in the world, we need a lot more renewable energy. And to combat climate change, we need a lot more renewable energy of all sorts,” Hsu said.

Other contributors to the Frontiers in Energy Research study include lead author Robert Piper, materials science and engineering doctoral student, who received support from the National Science Foundation; Trey Daunis MS’15, PhD’19 who now works at Max-IR Labs in Dallas; Weijie Xu MS’20, materials science and engineering doctoral student; and Dr. Kurt A. Schroder, chief technology officer at NovaCentrix.